Pvc Extruder Screw Design . each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more.

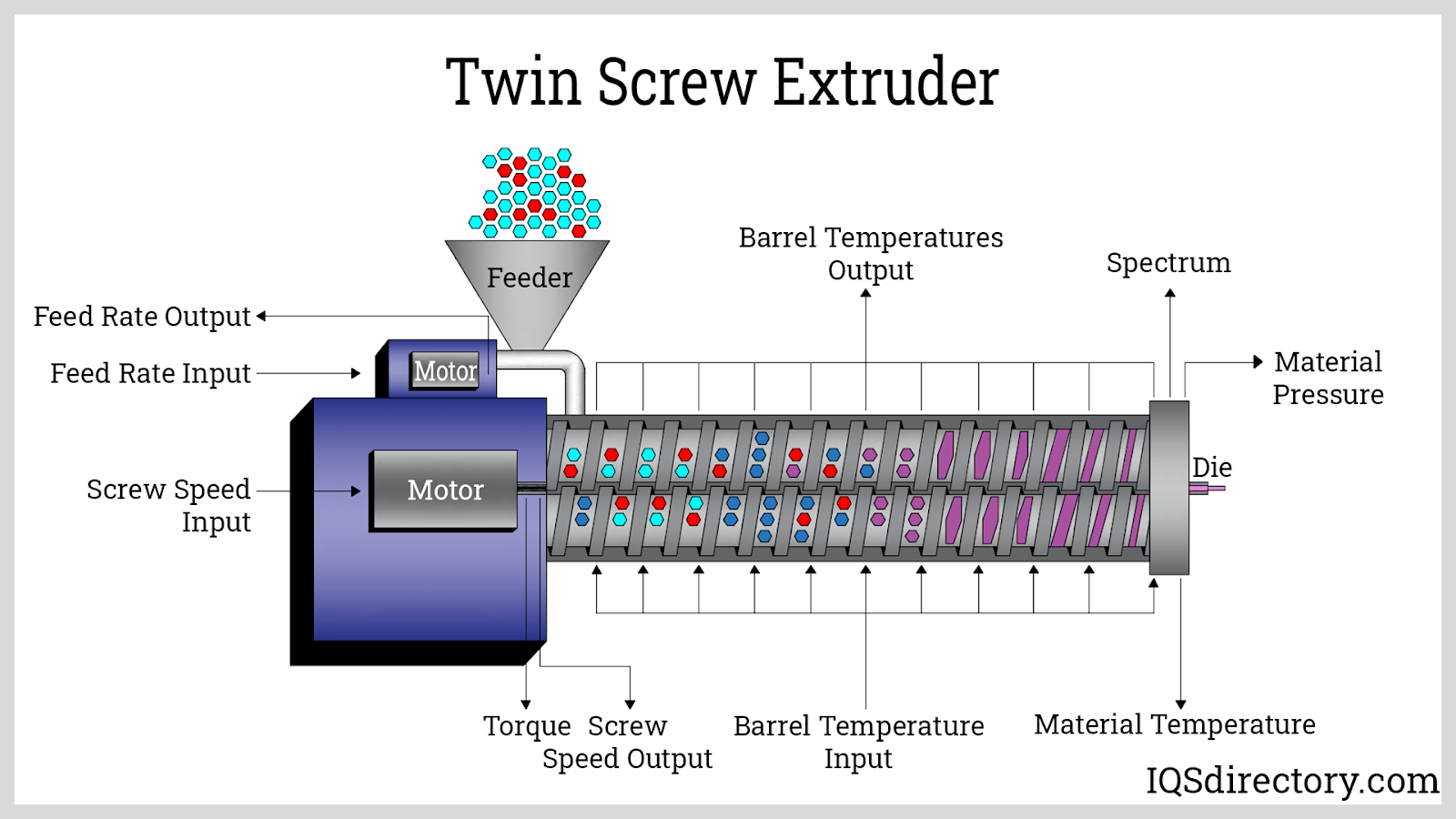

from www.iqsdirectory.com

First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc. familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more.

Plastic Extrusion What Is It? How Does It Work? Process

Pvc Extruder Screw Design the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc. the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more. familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance.

From www.alibaba.com

Pvc Extruder Screw Design And Barrel/conical Twin Screw And Cylinder Pvc Extruder Screw Design — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more. familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. — an intro to extrusion report that explains the basic principles of screws for. Pvc Extruder Screw Design.

From www.tradewheel.com

Buy Pvc Extruder Screw Design And Barrel/conical Twin Barrel Screw For Pvc Extruder Screw Design each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. First to be considered are the capabilities of the extruder, including horsepower, screw. Pvc Extruder Screw Design.

From www.omegabarrelscrew.com

CounterRotating Twin Screw Extruder Omega Machinery Pvc Extruder Screw Design familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more. each screw design is an exercise in finding the “sweet spot.” each polymer, each. Pvc Extruder Screw Design.

From www.researchgate.net

Schematic diagram of the extruder screw configuration. a Singlescrew Pvc Extruder Screw Design — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. — rigid pvc extruders may have accepted reduced screw wear life and. Pvc Extruder Screw Design.

From www.fareastnetwork.co.jp

A comprehensive explanation of the structure, length, thickness, design Pvc Extruder Screw Design First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc. — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. the selection of the proper screw for a given injection molding or extrusion application can be critical to its success.. Pvc Extruder Screw Design.

From www.cowinextrusion.com

Split Twin Screw Extruder for Thermoset Plastic Extrusion Line Cowin Pvc Extruder Screw Design each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. — rigid pvc extruders may have accepted reduced screw wear life and. Pvc Extruder Screw Design.

From www.rbplasticsmachinery.com

SingleScrew Plastics Extruder R&B Plastics Machinery Pvc Extruder Screw Design the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. First to be considered are the capabilities of the extruder, including horsepower, screw. Pvc Extruder Screw Design.

From www.twinscrewextruder-parts.com

PVC Plastic Extruder Screws And Barrels Twin Screw Extruder Elements Pvc Extruder Screw Design each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more. First to be considered are the capabilities of the. Pvc Extruder Screw Design.

From blmmaterial.en.made-in-china.com

PVC Extruder Screw Design and Barrel/Conical Twin Barrel Screw for Pvc Extruder Screw Design — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more. each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. the selection of the proper screw for a. Pvc Extruder Screw Design.

From www.yashiscrew.com

PVC extrusion screws and barrels, extruder wear partsConical Twin Pvc Extruder Screw Design familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more. — an intro to extrusion report that explains the basic principles of screws for. Pvc Extruder Screw Design.

From www.youtube.com

Conical twin extrusion screw and barrel How to choose conical twin Pvc Extruder Screw Design — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc.. Pvc Extruder Screw Design.

From paletrecycling.com

Best Extruder Screw DesignQingdao palet Pvc Extruder Screw Design each screw design is an exercise in finding the “sweet spot.” each polymer, each extruder, and each process requires a different design to optimize performance. — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. familiarity with the characteristics, benefits, and uses of each type of screw. Pvc Extruder Screw Design.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Pvc Extruder Screw Design First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc. the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and. Pvc Extruder Screw Design.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Pvc Extruder Screw Design First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc. the selection of the proper screw for a given injection molding or extrusion application can be critical to its success. familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. . Pvc Extruder Screw Design.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Pvc Extruder Screw Design familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing. Pvc Extruder Screw Design.

From www.indiamart.com

Screw And Barrel For Plastic Extruder, For Industrial at best price in Pvc Extruder Screw Design — an intro to extrusion report that explains the basic principles of screws for thermoplastics with helpful diagrams and formulae. familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make useful informed decisions. the selection of the proper screw for a given injection molding or extrusion application can be critical to. Pvc Extruder Screw Design.

From paulmurphyplastics.com

Plastic Extrusion • Paul Murphy Plastics Pvc Extruder Screw Design First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more. — an intro to extrusion report that explains the basic principles of screws for thermoplastics with. Pvc Extruder Screw Design.

From www.rbplasticsmachinery.com

SingleScrew Plastics Extruder R&B Plastics Machinery Pvc Extruder Screw Design First to be considered are the capabilities of the extruder, including horsepower, screw speed, bore size, l/d, etc. — rigid pvc extruders may have accepted reduced screw wear life and output as a cost of doing business and adapted by using more. familiarity with the characteristics, benefits, and uses of each type of screw design helps producers make. Pvc Extruder Screw Design.